ETERNA EFOLD 650/900/1100

Automatic Folder Gluers

EFOLD 650/900/1100 Folder Gluer for Micro-corrugated

& Cardboard Box

- Strong and steady construction to improve running conditions;

- Modular design for easy adaptation to accommodate various boxes from food, pharma to cosmetic, electronics and so on;

- New HMI with icon design for easy communication ;

- Wired for connection with other equipment including smart logistic, electronic gluing, inspection system and so on;

- Equipped with high speed electronic counting device for accurate box count;

- Special B-Type lower glue pot for easy maintenance and glue wheel exchange;

- Smart modular design for easy upgrade according to customers’ requirements.

C-2: 650/900/1100 mm

C-3: 650/900/1100 mm

C-6: 650/900/1100 mm

EFOLD 1100 ELITE SHOWN

EFOLD 650 | 900 | 1100 ELITE

Card board:200-800 g/m²

Corrugated board:N / E / F Flute

Max. Belt Speed:320 m/min (420 m/min as optional)

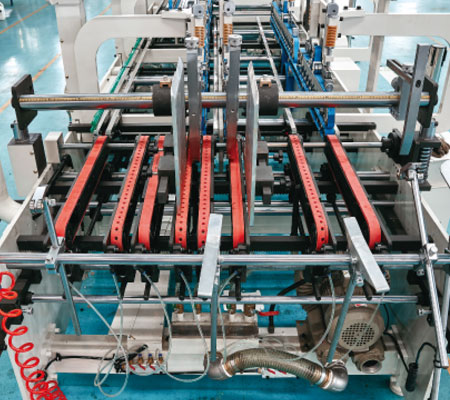

Feeder Section

Two feeder gates for standard box, and one assist feeder gate for odd and wider boxes.

Vibration system with supporting bars for efficiency and stable feeding.

Eight individually adjustable feed belts ensure easy setup and smooth feeding.

Optional suction feeding system.

lock bottom section

Optional servo-drive back fold system.

User-friendly operation and stable bottom lock system is ideal for mounting.

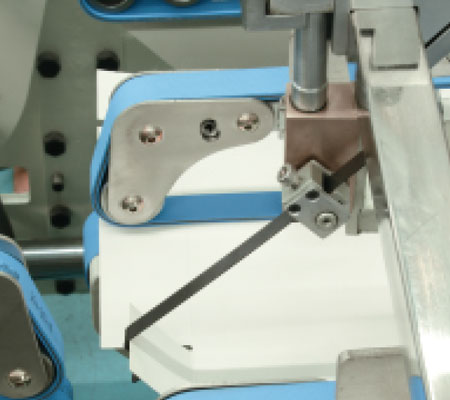

GLUING SYSTEM

Standard lower glue pots on left and right side.

Optional upper glue pots on left and right side.

Optional electronic gluing system.

DELIVERY SECTION

Pneumatic upper carrier is adjustable vertically to obtain perfect pressure on glued boxes.

Extra sponge belt for positive pressing at lower area of the box shingled delivery.

Ready to be in-line with J-packer (optional) to save manpower and increase package efficiency at high speed production.

Feeder Section

Two feeder gates for standard box, and one assist feeder gate for odd and wider boxes.

Vibration system with supporting bars for efficiency and stable feeding.

Eight individually adjustable feed belts ensure easy setup and smooth feeding.

Optional suction feeding system.

Gluing System

Standard lower glue pots, each left and right side.

Optional upper glue pots, each left and right side.

Optional electronic gluing system.

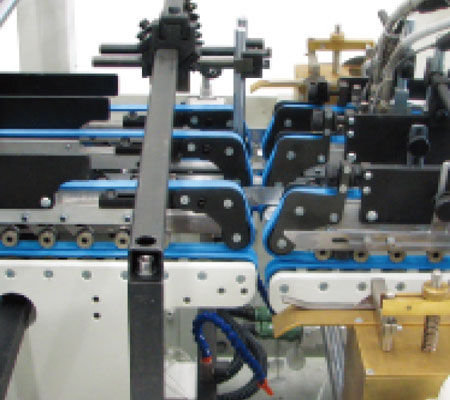

Lockbottom Section

Optional servo-drive back fold system.

User-friendly & stable bottom lock system ideal for mounting.

Trombone Section

Box jam-up detector.

Batch counter as standard.

Pneumatic stopper at conveyor section to prevent glued box from fish tailing.

Stopper at Trombone section ensures box lead edge squaring.

Conveyor compression section

Pneumatic upper carrier is adjustable vertically to obtain perfect pressure on glued boxes.

Extra sponge belt for positive pressing at lower area of the box shingled delivery.

Ready to be in-line with J-packer (optional) to save manpower and increase package efficiency at high speed production.

SPECIFICATIONS

Stock Range

Max. Belt Speed

Jogging Speed

Main Motor

Overall Length

Total Weight

Solid board, 200-800g/m2. Corrugated N, E, F Flute

320m/min. (420 m/min as optional

20 m/min

11KW

650 - 12.7x 2 m | 900 - 12.7 x 2.3 m | 1100 - 12.7 x 2.6 m

650 - 6 Ton | 900 - 6.5 Ton | 1100 - 7 Ton

Our Offices

North America Operations Headquarters

Canada

#1 - 1500 Valmont Way Richmond, British Columbia Canada, V6V 1Y4

Toll Free : (888) 853-4760

Local: (604) 278-2027

Fax: (604) 278-1005

Email: info@brausse.com

Northern

Division

USA

1650 West End Blvd. St. Louis Park, MN 55416

Suite 100

Toll Free : (888) 272-8773

Local: (952) 767-9725

Fax: (952) 767-9729

Email: info@brausse.com