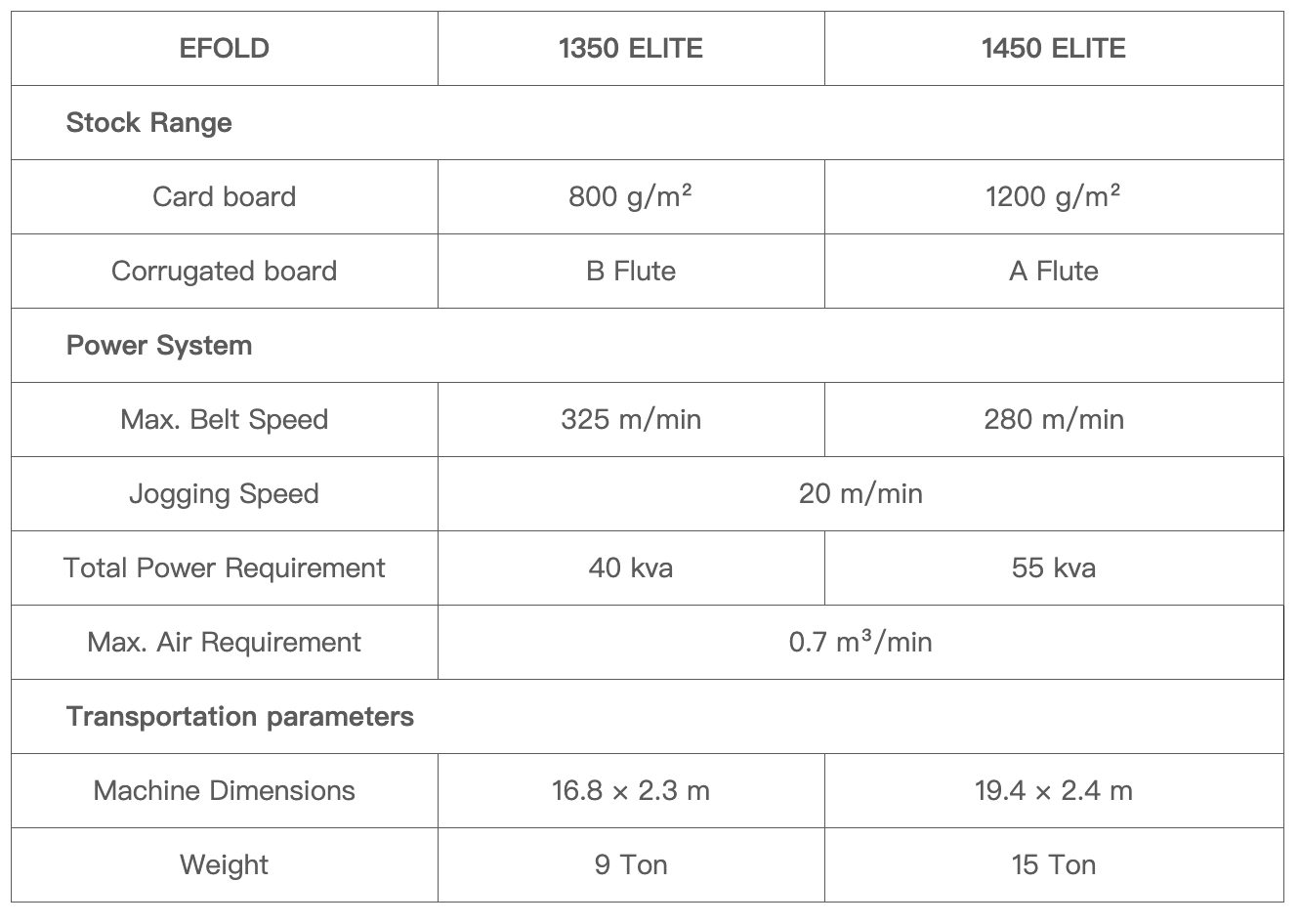

ETERNA EFOLD 1350 | 1450 Elite Folder Gluer

for Micro-corrugated & Cardboard Box

Feeder section

Two feeder gates for standard box, and one assist feeder gate for odd and wider boxes.

Vibration pile supporting bars for efficiency and stable feeding.

Eight individually adjustable feed belts ensure easy setup and smooth feeding.

Suction feeding system (optional for TB1100/TB1350 models).

SIDE ALIGNMENT SECTION

Side alignment section is optional between feeder and pre-break section.

pre-breaking section

Three carriers throughout with split upper carriers in pre-breaking section.

Motorized carrier positioning system applied on whole machine as standard for TB1450 (optional for TB1100/TB1350 models).

LOCK BOTTOM SECTION

User-friendly & stable bottom lock system ideal for mounting.

Optional servo-drive system for 4 corner and 6 corner box production.

gluing

Standard lower glue pots on left and right side for straight line box.

Optional upper glue pots on left and right side for crash lock bottom box

Non-contact electronic gluing system is a must option for 4/6 corner box.

final fold section

Independent cylinder-drive upper carrier specially suited for corrugated box production.

Motorized carrier positioning system applied on entire machine as standard for TB1450.

TB1100/TB1350 allows for upgrade with motorized carrier positioning system as an option.

Trombone Section (Transfer)

Jam-up detector.

Batch counter as standard and easy set up via HMI.

Finger-type stopper at outlet trombone section ensures the front flap is aligned.

Delivery Section

Pneumatic upper carrier is adjustable vertically to obtain perfect pressure on glued boxes.

Extra sponge belt for positive pressing at lower area of the box shingled delivery.

Squaring device at entrance of Conveyor section to prevent glued box from fish tailing.

Model TB1100, TB1350 are able to fold and glue up to B-flute boxes; TB1450 able to fold and glue up to A flute boxes.

Independent cylinder-drive upper carrier, specially suited for corrugated production.

Remote control throughout entire machine for operator-friendly use and easy setup.

Modular design allows for upgrades in the future for more demanding jobs.

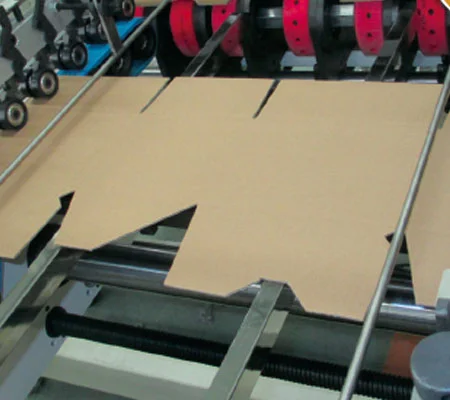

Feeder Section

Two feeder gates for standard box, and one assist feeder gate for odd and wider boxes.

Vibration system with supporting bars for efficiency and stable feeding.

Eight individually adjustable feed belts ensure easy setup and smooth feeding.

Optional suction feeding system.

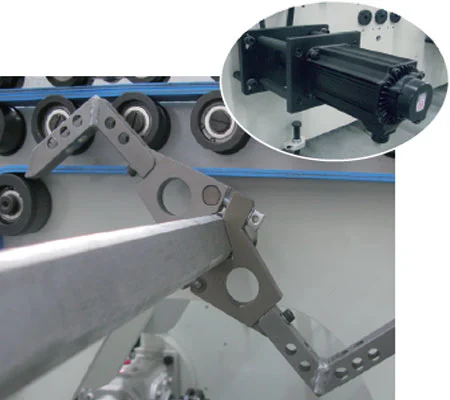

Final Folding Section

Independent cylinder-drive upper carrier specially suited for corrugated production.

Motorized carrier positioning system applied on entire machine as standard for TB1450.

(TB1100/TB1350 allows for upgrades with motorized carrier positioning system as an option).

Gluing System

Standard lower glue pots on left and right side.

Optional upper glue pots on left and right side.

Optional electronic gluing system.

Lock bottom Section

Optional servo-drive back fold system.

User-friendly & stable bottom lock system ideal for mounting.

Trombone Section

Box jam-up detector.

Batch counter as standard.

Pneumatic stopper at conveyor section to prevent glued box from fish tailing.

Stopper at trombone section ensures box lead edge squaring.

Conveyor compression section.

Pneumatic upper carrier is adjustable vertically to obtain proper pressure on glued boxes.

Extra sponge belt for positive pressing at lower area of the box shingled delivery.

Our Offices

North America Operations Headquarters

Canada

#1 - 1500 Valmont Way Richmond, British Columbia Canada, V6V 1Y4

Toll Free : (888) 853-4760

Local: (604) 278-2027

Fax: (604) 278-1005

Email: info@brausse.com

Northern

Division

USA

1650 West End Blvd. St. Louis Park, MN 55416

Suite 100

Toll Free : (888) 272-8773

Local: (952) 767-9725

Fax: (952) 767-9729

Email: info@brausse.com