E-LINE - FULL SYSTEM AUTOMATION SOLUTION

ETERNA's System Automation Solution integrates multiple single machines into one equipment set to reduce operators and increase production efficiency to maximize production capacity.

e-LOAD The Feeding Module

The e-LOAD can be connected with printing presses and flatbed die-cutters. Reliable and compact, it requires no operator interaction at all. It manages the uninterrupted loading of corrugated board into the die-cutter’s feeder. At a stroke, it eliminates any slowing of line speed due to operator fatigue. Furthermore, it allows you to reduce your headcount by at least two operators per shift and guarantees the continual functioning of your die-cutter.

Pile-Lifting Table

The pile is centered by means of photocells controlling the lateral movement of the table.

Pusher

A batch of a specified height is taken from the top of the pile without disturbing it.

Joggers

The batch of sheets is lifted off the belt to assist the action of the joggers. A blower assists with aligning the most difficult types of cardboard.

Pile Evacuation

The empty pallet, the carrier plate, or remains of the pile are evacuated on rollers in the direction of travel, and then laterally by means of a pusher.

GAUGE

The shingled stream is arranged by a mobile gauge.

Shingled Stream

The machine is fed precisely, regularly, and continuously.

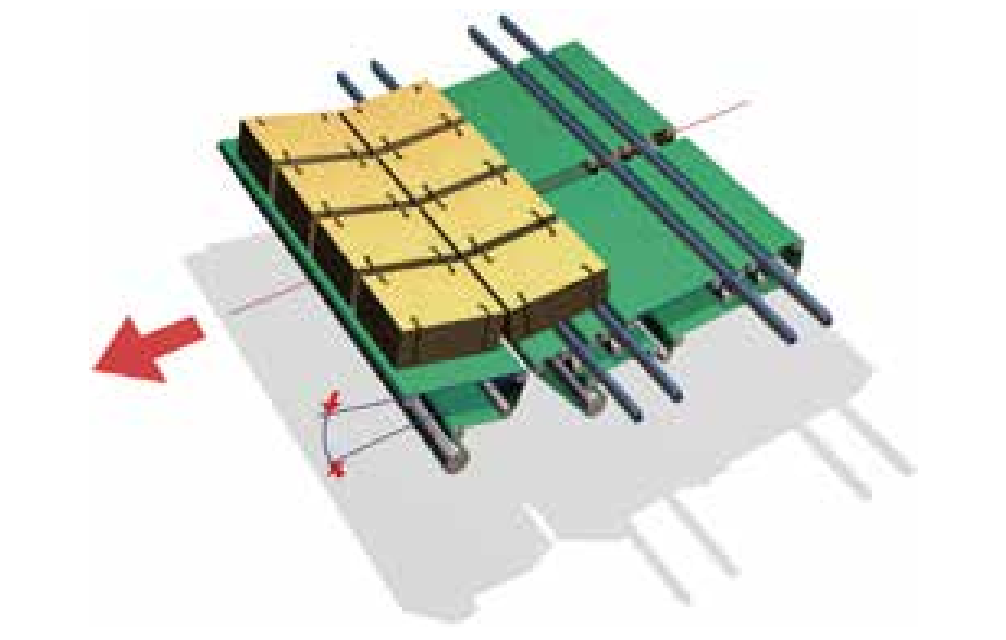

e-BREAK The Breaking Module

The e-BREAK is a compact, high-performance stand-alone separator and layer-arranger. Capable of intelligent and completely automated management of flows, it can be entirely adapted to your requirements. The e-BREAK will save you between two and six operators and, again, will ensure the uninterrupted functioning of your die-cutter.

Cross Separation

The sheet is introduced and placed in the middle of the gripper 1.

Each row is broken one after the other.

The layer of board moves along the line to be broken.

The apron of gripper 2 does the angular breaking. The separated layer of board is evacuated by means of rollers.

e-PAL The Palletizing Module

The e-PAL can automatically stack all layers directly on rollers, on pallet, or on plate. The e-PAL can be installed with the pile delivery in-line or at right angle at the line. It is designed to greatly improve efficiency and reduce labor intensity.

JOGGER

The stack can be automatically arranged and aligned in a specified way, which can achieve complicated arrangement combinations and improve production efficiency. The jogger can make the stack squared.

Palletizing

The layers are transported by belts and forks. Each layer, and the whole pile, is squared on all 4 sides.

STACKING

The palletizer runs smoothly until all the stacks are evacuated, neat, and squared.

TERMS AND CONDITIONS

INSTALLATION:

Equipment installation and operator instruction will be conducted by the Seller's technicians for a period not exceeding seven (7) calendar days. Wages, hotel accommodation and return airfare for the technicians during installation period as well as transportation of Equipment from port to buyer's plant will be at seller's account. All other costs to be incurred by installation such as cost of rigging, site preparation, electrical connection to the Equipment, insurance premium for moving and rigging and any extra expenses for making the access to the premises are not included and shall be at buyer's account.

WARRANTY:

The Sellers warrant that the Equipment will be free from defects in materials and workmanship when it is used properly and in accordance with the directions of use for the Equipment for a period of 12 months counting from the 15th day of arrival at the destination or the date of arrival at the end users premises, whichever comes first. The remedy for breach of warranty shall be limited to replacement of defective parts (mechanical and electrical), repairing and labor related. Consequential damages for breach of warranty where the claimed loss is commercial are excluded. There are no expressed warranties beyond the stated in writing.

The warranty set forth above is the only warranty by the Seller with respect to the Equipment specified in this Quotation. No other warranties of any kind, whether statutory, written, oral, expressed or implied, including but not limited to, warranties of fitness for a particular purpose or merchantability, shall apply.

THIS WARRANTY WILL BECOME VOID IMMEDIATELY IF THERE IS A BREACH OF CONTRACT BY THE BUYER/S OR IF THE EQUIPMENT IS MOVED, MODIFIED, OR IF ANY MAJOR REPAIR IS PERFORMED BY UNAUTHORIZED PERSONNEL WITHOUT THE SELLER’S WRITTEN CONSENT.

Our Offices

North America Operations Headquarters

Canada

#1 - 1500 Valmont Way Richmond, British Columbia Canada, V6V 1Y4

Toll Free : (888) 853-4760

Local: (604) 278-2027

Fax: (604) 278-1005

Email: info@brausse.com

Northern

Division

USA

1650 West End Blvd. St. Louis Park,

MN 55416 Suite 100

Toll Free : (888) 272-8773

Local: (952) 767-9725

Fax: (952) 767-9729

Email: info@brausse.com