ETERNA TA SERIES II Automatic Folder Gluers

Folder Gluers adopt a new modular design, suitable for various types of boxes. According to actual production demand, C3 (Straight line box) can be conveniently upgraded to C4 (4 corner) and C6 (6 corner), add Turn Section, second pre-folding section, quality detector section.

The drive of the whole machine adopts Group Technology, less noise and consumption, saving 15% on maintenance cost.

Feeder section, main machine section, trombone section, and delivery section all use an independent motor, ensuring smooth feeding and delivery.

TA 550 Shown

FEEDER SECTION

Side guides and feeder gates can be pneumatically lifted up.

Belt cleaning brush with easy angle adjustment.

Supporting bars with vibration motor.

A/C motor for variable frequency speed control.

Suction Feeding System as an option.

GLUING SYSTEM

Standard lower glue pots on each operation/drive side.

Non-contact gluing system as an option for lock bottom box.

SIDE ALIGNMENT SECTION

Side alignment section can be retrofitted between feeder and pre-breaking section.

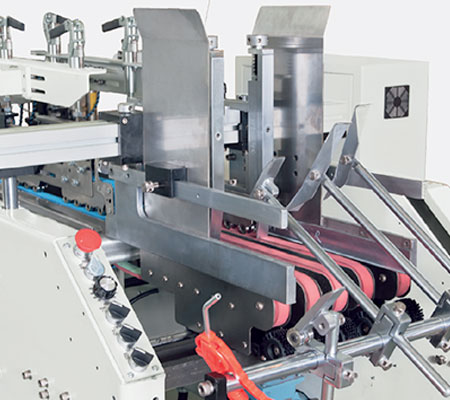

PRE-BREAKING SECTION

2-carrier construction with pre-breaking sword (180) and pre-break belt (135) .

Sectional upper carrier can be telescopically adjusted to meet a wide range of boxes.

Uniquely designed upper carrier to protect the spring foot from damage if operated wrongly.

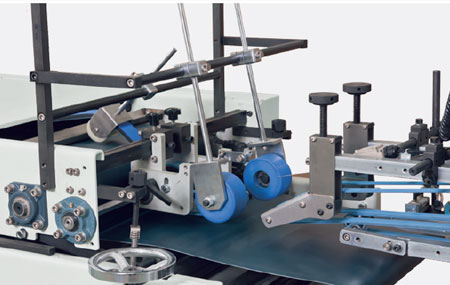

LOCK BOTTOM SECTION

2-carrier construction. Sectional upper carrier is beneficial for correcting irregular box performance.

Uniquely designed Mini Back Folding Unit can be retrofitted for standard 4-corner box. (option)

FINAL FOLD SECTION

Left/Right outward folding belts with speed micro-adjustment.

Uniquely designed folding belt unit is extendable per box size, without adjusting belt tension.

TROMBONE SECTION

High speed kick counter and Jam detector as standard.

Upper/lower belts can be telescopically adjusted easily.

AC motor for variable frequency speed control.

Ready for retrofit In-Line Ejector Device. (options)