BRAUSSE TA SERIES I Automatic Folder Gluers

650/900/1100 TA Series Folder Gluer for Micro-corrugated

& Cardboard Box

TA series folder gluer is suitable for micro-corrugated & cardboard box, solid board up to 800g/m2, corrugated up to E-Flute. The fundamental pattern includes straight line, double sides, crash-bottom lock, 4/6-corner. There are 4 different widths and 3 different versions.

C-2: 650/900/1100 mm

C-3: 650/900/1100 mm

C-6: 650/900/1100 mm

TA 1100 Shown

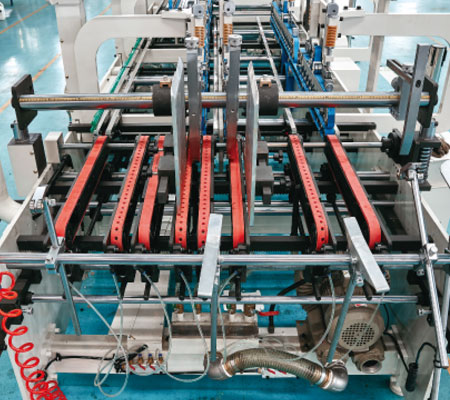

Feeder Section

Two feeder gates for standard box, and one assist feeder gate for odd and wider boxes.

Vibration system with supporting bars for efficiency and stable feeding.

Eight individually adjustable feed belts ensure easy setup and smooth feeding.

Optional suction feeding system.

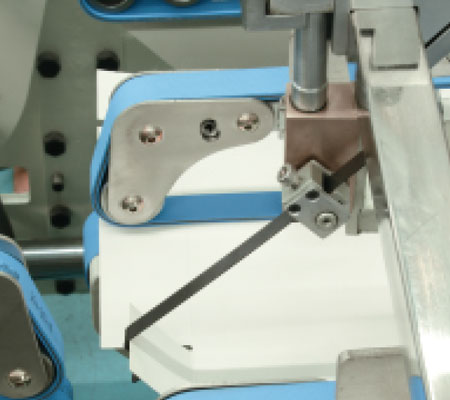

lock bottom section

Optional servo-drive back fold system.

User-friendly operation and stable bottom lock system is ideal for mounting.

GLUING SYSTEM

Standard lower glue pots on left and right side.

Optional upper glue pots on left and right side.

Optional electronic gluing system.

DELIVERY SECTION

Pneumatic upper carrier is adjustable vertically to obtain perfect pressure on glued boxes.

Extra sponge belt for positive pressing at lower area of the box shingled delivery.

Ready to be in-line with J-packer (optional) to save manpower and increase package efficiency at high speed production.

Feeder Section

Two feeder gates for standard box, and one assist feeder gate for odd and wider boxes.

Vibration system with supporting bars for efficiency and stable feeding.

Eight individually adjustable feed belts ensure easy setup and smooth feeding.

Optional suction feeding system.

Gluing System

Standard lower glue pots, each left and right side.

Optional upper glue pots, each left and right side.

Optional electronic gluing system.

Lockbottom Section

Optional servo-drive back fold system.

User-friendly & stable bottom lock system ideal for mounting.

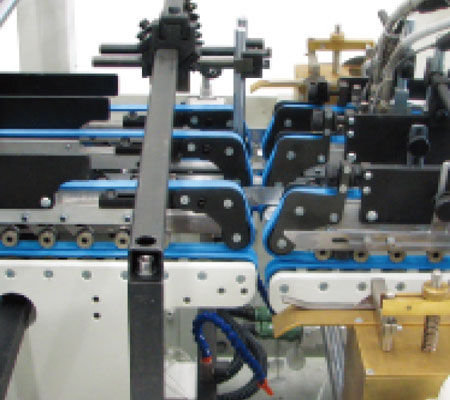

Trombone Section

Box jam-up detector.

Batch counter as standard.

Pneumatic stopper at conveyor section to prevent glued box from fish tailing.

Stopper at Trombone section ensures box lead edge squaring.

Conveyor compression section

Pneumatic upper carrier is adjustable vertically to obtain perfect pressure on glued boxes.

Extra sponge belt for positive pressing at lower area of the box shingled delivery.

Ready to be in-line with J-packer (optional) to save manpower and increase package efficiency at high speed production.

SPECIFICATIONS

|

|

TA650 |

TA900 |

TA1100 |

|

Max Belt Speed |

425m/min |

425 m/min |

425 m/min |

|

Main Power |

15Kw |

22Kw |

22Kw |

|

Overall Length |

12140 mm |

12740 mm |

12740 mm |

|

Total weight |

7000 kg(C3) |

7800 kg(C3) |

8000 kg(C3) |

|

TECHANICAL DATA |

TA 650 |

TA900 |

TA1100 |

|

A mm(in) |

100-700(39-27.5) 78-700(3-27.5)** |

120-900(4.7-35.4) 80-900(3.1-35.4)** |

120-1100(4.7-43.3) 80-1100(3.1-43.3)** |

|

B mm(in) |

55-800(2.2-31.5) |

55-900(2.2-35.4) |

55-900(2.2-35.4) |

|

C mm(in) |

55-340(2.2-13.4) |

55-440(2.2-17.3) |

55-540(2.2-21.2) |

|

D mm(in) |

8(0.3) |

8(0.3) |

8(0.3) |

|

|

(**with small box folding device) |

||

|

A mm(in) |

160-500 (6.3-19.7) |

175-650 (6.9-25.6) |

175-710 (6.9-28) |

|

B mm(in) |

160-70 (6.3 – 27.5) |

160-900(6.3-35.4) |

160-900 (6.3-35.4) |

|

C min. mm(in) |

30-100 (1.2 – 3.9) |

30-150(1.2-5.9) |

30-150(1.2-5.9) |

|

D min. mm(in) |

- |

- |

85-830 |

|

A mm(in) |

150-675(5.9-26.6) |

160-875(6.3-34.4) |

160-1075(6.3-42.3) |

|

B mm(in) |

10-800(4.7-31.5) |

150-900(5.9-35.4) |

150-900(5.9-35.4) |

|

C min. mm(in) |

40(1.57) |

47(1.85) |

47(1.85) |

|

D min. mm(in) |

30(1.2) |

30(1.2) |

30(1.2) |

|

E min. mm(in) |

65(2.56) |

65(2.56) |

65(2.56) |

|

F min. mm(in) |

28(1.1) |

28(1.1) |

28(1.1) |

|

A mm(in) |

160-550 (6.3-21.6) |

175-700 (6.9-27.5) |

175-760 (6.9-30) |

|

B mm(in) |

160-700 (6.3-27.5) |

160-900 (6.3-35.4) |

160-900 (6.3-35.4) |

|

D mm(in) |

30-10 (1.2-3.9) |

30-150 (1.2-5.9) |

30-150 (1.2-5.9) |

|

A mm(in) |

280-600 (11.0-23.6) |

300-850 (11.8-33.5) |

300-1050 (11.8-41.3) |

|

B mm(in) |

160-700 (6.3-27.5) |

160-900 (6.3-35.4) |

160-900 (6.3-35.4) |

|

D mm(in) |

30-10 (1.2-3.9) |

30-150 (1.2-5.9) |

30-150 (1.2-5.9) |